MECHANICAL

1000 m2 of air-conditioned workshop space and modern manufacturing resources (NC lathes, 3, 4 and 5-axis machining centres, flat and cylindrical grinding machines, wire EDM, laser marking) to offer our customers quality and responsiveness.

- Capacity of the 3 and 4-axis centres : 2000 mm x 1000 mm x 600 mm

- Capacacity of the 5-axis centres : up to Ø650 mm

- Capacity of the turning machines : Ø1120 mm x 1000 mm

- Flat grinding capacity : 600 mm x 300 mm

- Cylindrical grinding capacity : Ø340 mm x 1000 mm

- Wire EDM capacity : 550 mm x 350 mm x 400 mm

We work with all types of materials: steel, stainless steel, aluminum, inconel, titanium, bronze, copper, POM, PEHD, PA6, etc.

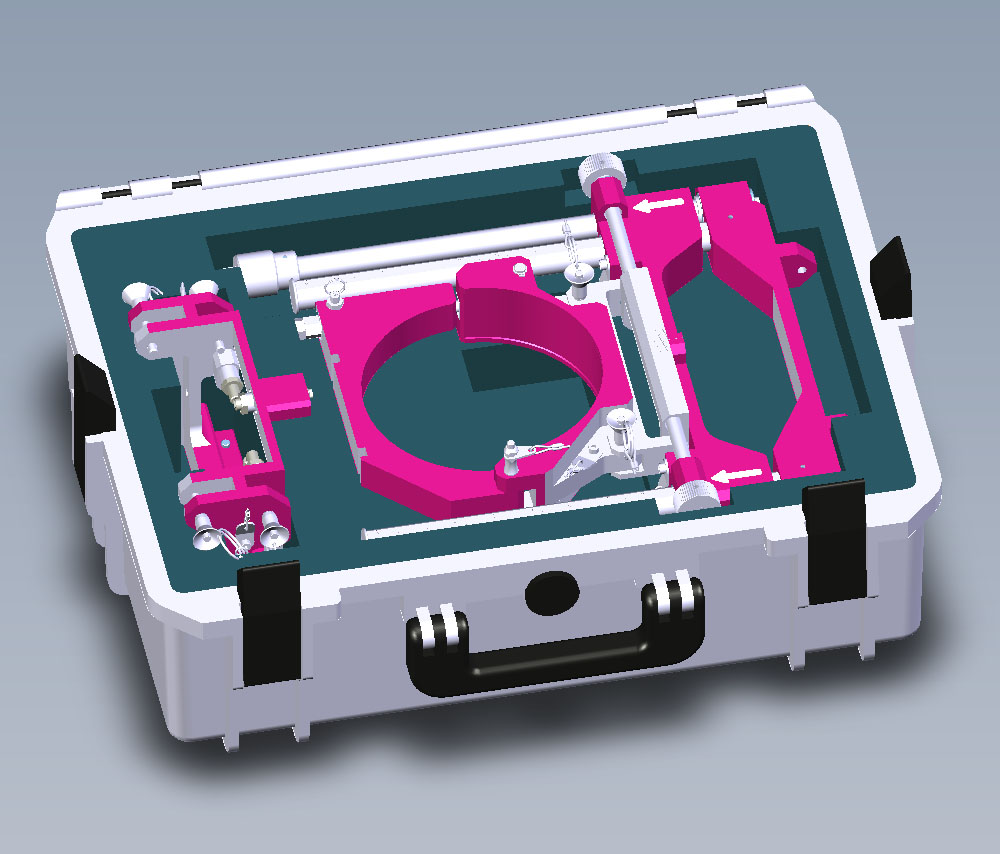

CAD & CAM

A team of professionals and CAD/CAM software (Top Solid, Go2Cam…) which enables us to exchange 3D models.

We provide our customers with technical support and also draw up technical drawings.

QUALITY

We are ISO 9001 and ISO 14001 certified.

The quality of our work is the basis of our commitment, and our entire organization works to achieve total customer satisfaction.

We have a wide range of testing equipment (marble, measuring column, palmer, gauge blocks, three-dimensional measuring machine, etc.) and subcontract the tests we cannot carry out in-house (lifting resistance, etc.).